The global production of cement, primarily for the manufacture of concrete, accounts for about 8% of anthropogenic carbon dioxide emissions. This article highlights a number of technical solutions for reducing the level of carbon dioxide emissions during cement production and examines international patent application trends over the last 20 years. The results indicate that United States and European applicants dominate international patent applications in the field, with, perhaps surprisingly, relatively few international applications from Asian applicants.

Cement is a fine, powdery substance used as a binder in the manufacture of construction materials. When cement is mixed with water, sand, and aggregate it forms concrete, which, after water, is the most widely used material in the world.

Cement is largely made from limestone (calcium carbonate) and clay through heating at high temperature (over 1400 °C) in a kiln to form what is known as clinker. These high temperatures are achieved by burning coal, petroleum coke, or natural gas. During cement manufacture large quantities of carbon dioxide are released, both as a chemical by-product of cement production, through conversion of the calcium carbonate to calcium oxide, and from burning of the fossil fuels. The emissions from burning fuel represent about half of the total emissions, and even if the energy required for heating could in principle be substituted with energy generated from renewable sources (solar, wind, green hydrogen, etc.), the other half of the emissions is inherent to the chemistry of the process. Global cement production is currently around four billion tonnes per year and accounts for approximately 8% of global carbon dioxide emissions.

In order to meet future global emissions targets the reduction of carbon monoxide emissions from cement manufacture is generally regarded as one of the most challenging.

Technical areas

Sustainable cement production has focused on two main technical areas, 1) reduction of the amount of carbon dioxide produced during cement manufacture and, 2) sequestration of the produced carbon dioxide, so that less is released into the atmosphere.

According to the Global Cement and Concrete Association (Getting to Net Zero (gccassociation.org)), these technical areas are each projected to contribute about 50% to net zero by 2050.

Some exemplary topics of research into sustainable cement include:

- Efficiency in design and construction of cement manufacturing facilities

- Fuel reduction through improved process efficiencies

- Replacement of fossil fuels with alternative fuels, such as waste-derived fuels, including where the alternative fuel may be incorporated into the cement at high temperature

- Reduction in the proportion of clinker in cement by partially replacing with supplementary cementitious materials (SCMs) such as fly ash or ground blast furnace slag

- Development of new cement formulations which require less energy to produce or release less carbon dioxide during high temperature processing, for example through the use of geopolymer binders or carbonatable binders

- Increase in the use of recycled cement

- Implementation of carbon capture and storage (CCS) to capture carbon dioxide emissions and store them underground or utilise in other processes

- Introduction of carbon dioxide into concrete, for example by injection as a gas during mixing and curing. As well as fixing surplus carbon dioxide, this may improve the strength of concrete and therefore reduce the amount of cement required

Patent trends

International patent application publications (PCT applications) represent a fair proxy for relatively significant developments in a technical field of endeavour. We therefore searched for international patent applications published between 2004 and 2024 in the two main technical areas mentioned above:

- reduction of the amount of carbon dioxide produced during cement manufacture and,

- sequestration of the produced carbon dioxide, so that less is released into the atmosphere.

Reduction in produced carbon dioxide

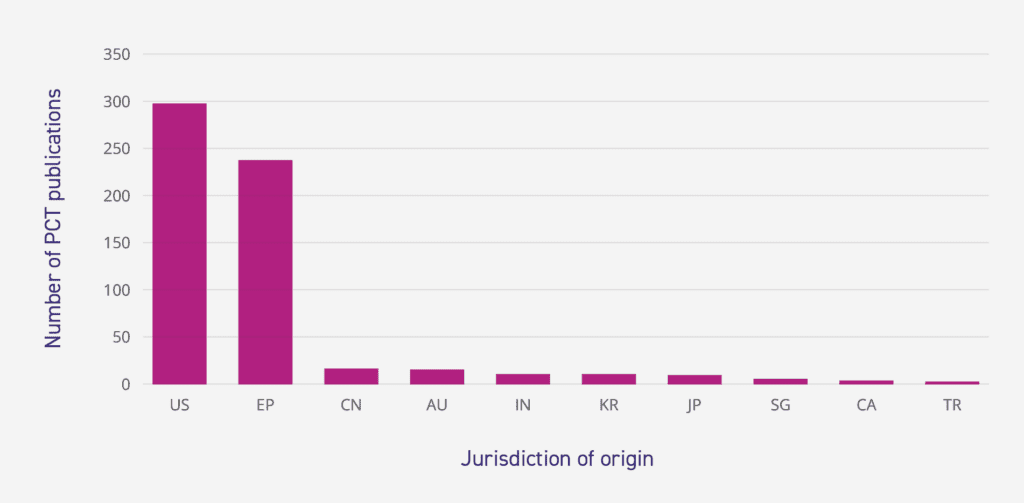

Figure 1 illustrates the evolution of international patent applications in technical area 1) from 2004 to 2024.

From 2004 to 2020 there was a modest increase in the number of publications per year, however in the last three years the numbers have increased dramatically, likely driven by an increase in development efforts to address carbon dioxide production during cement manufacture.

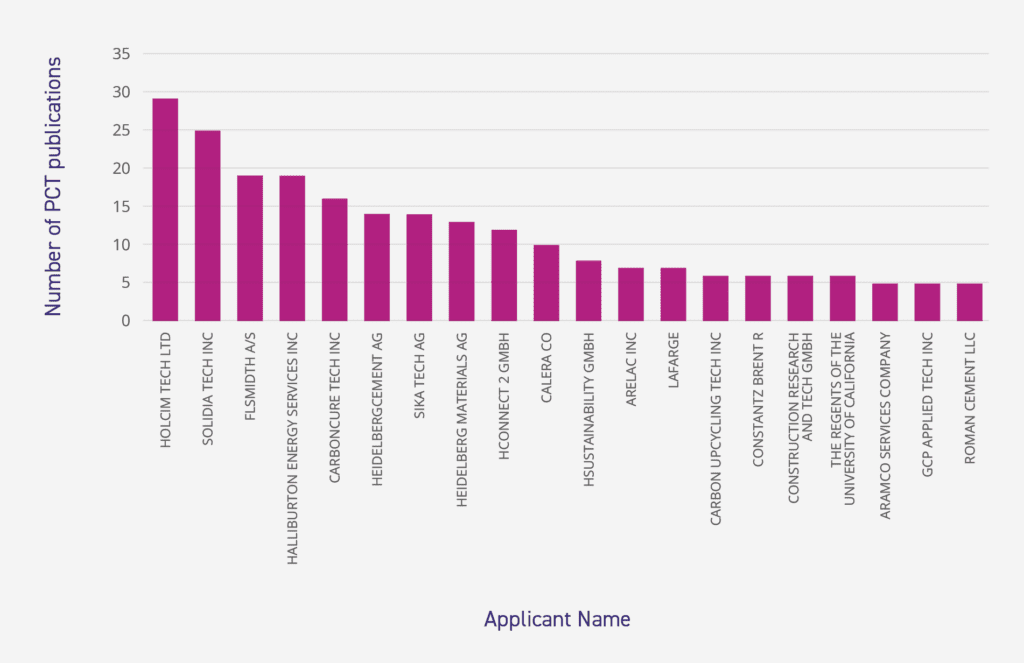

Figure 2 illustrates the top geographical areas in which patent applicants reside.

The vast majority of patent applicants are from the US and Europe. Perhaps surprisingly, the number of applications filed by applicants from China is relatively low, despite the fact that China accounts for more than half the global production of cement. Pleasingly, Australia (AU) performs relatively well in this metric, suggesting an active local ecosystem in concrete innovation.

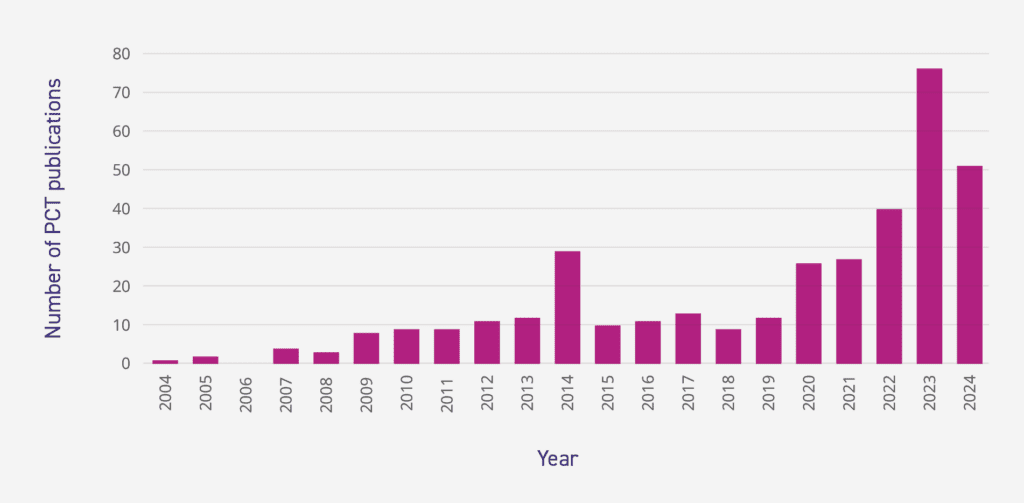

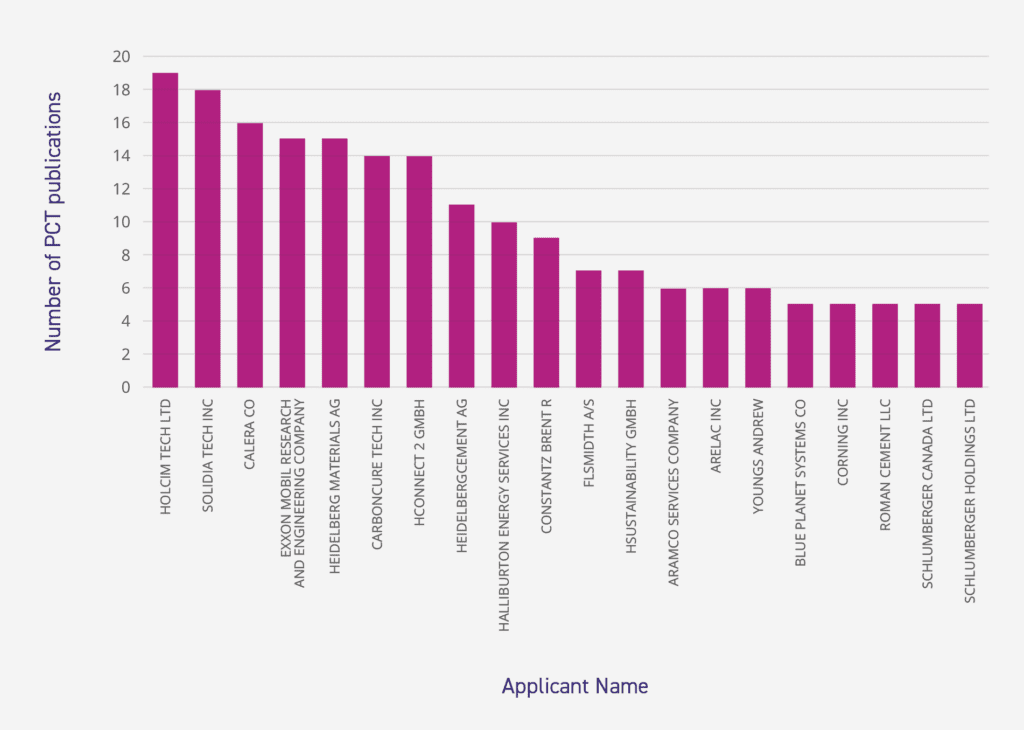

Figure 3 illustrates the top applicants.

Given the top geographical areas, it is unsurprising that the top applicants predominantly come from the US and Europe. For example, the top two filers, Holcim Tech Ltd and Solidia Tech Inc, are companies based in Switzerland and the US respectively.

Sequestration of produced carbon dioxide

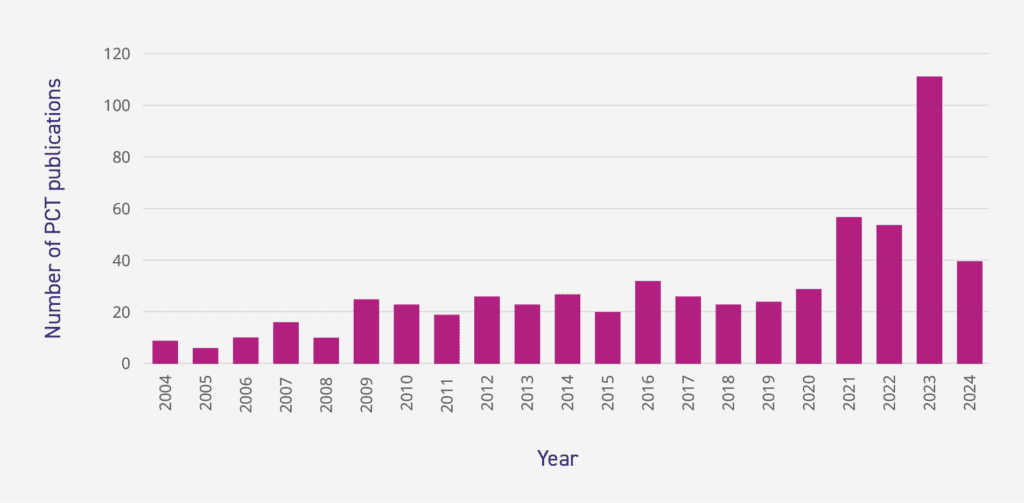

Figure 4 illustrates the evolution of international patent applications in technical area 2) from 2004 to 2024.

International patent publications in technical area 2) show a similar trend to publications in technical area 1), with a surge in numbers since 2019. The spike in numbers in 2014 was due to a single applicant filing multiple applications on one day.

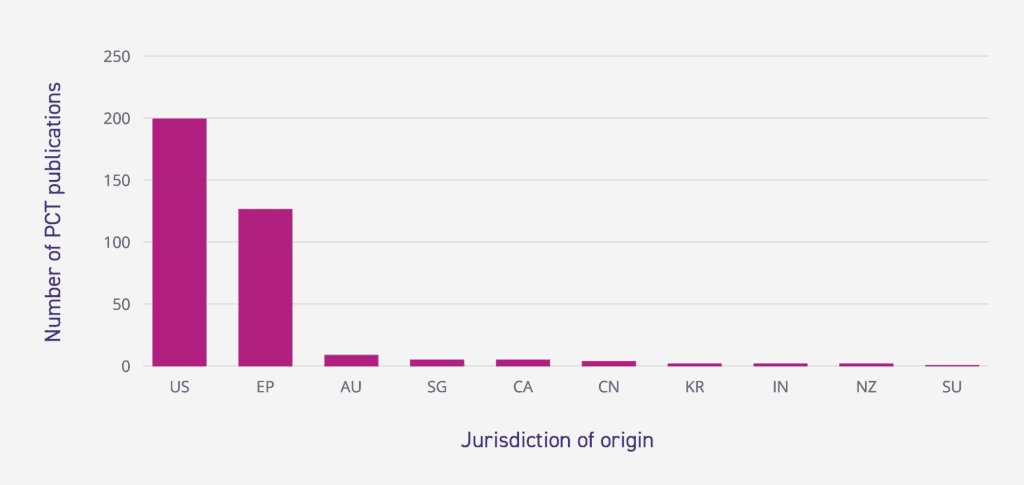

Figure 5 illustrates the top geographical areas in which patent applicants reside.

As with technical area 1), US and European based applicants dominate filings and Australian applicants once again perform reasonably well in this space. As was the case for technical area 1), Chinese applicants do not appear to be filing high numbers of international patent applications in technical area 2).

Figure 6 illustrates the top applicants.

The top applicants in technical area 2) closely relate to the top 20 applicants returned in the search for technical area 1), with 14 of the top 20 applicants being shared between the two technical areas. The top two applicants, Holcim Tech Ltd and Solidia Tech Inc, remain the same. Exxon Mobil is a notable addition to the companies returned in technical area 2), being the fourth largest patent filer in this space.

Further remarks

One interesting finding from our patent searching is the relatively low number of international patent applications owned by Chinese applicants. This contrasts with most fields of technology where Chinese applicants are typically one of the top filers of international patent applications.

One possible reason could be that the Chinese cement industry has historically been largely domestic in nature and only a small fraction of produced cement was exported. Therefore, there may have been no particular incentive to pursue patent protection in markets where Chinese companies are not competing.

FPA Patent Attorneys has a coordinated CleanTech team comprising patent professionals with chemical and engineering expertise. Please contact us to discuss your cement technology developments.